Call: +919822303472

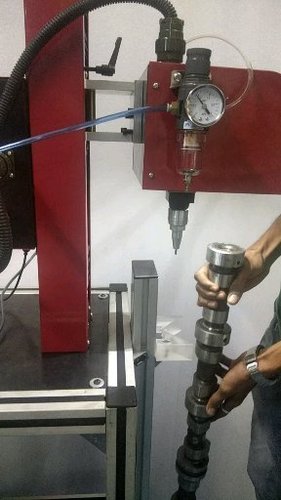

Motorcycle Parts Marking Machine

MOQ : 1 Unit

Motorcycle Parts Marking Machine Specification

- Marking Area

- 110mm x 110mm (Standard), Optional Up to 300mm

- Marking Speed

- â¤7000mm/s

- Condition

- New

- Laser Type

- Other

- CNC

- Yes

- Cooling Mode

- Other

- Control Software

- EZCAD

- Accuracy

- ±0.01 mm

- Power

- 20W / 30W / 50W (Optional)

- Dimensions

- 800mm x 650mm x 1450mm

- Supported Formats

- PLT, BMP, DXF, JPG, TIF, AI

- Focus Method

- Manual / Auto

- Material Compatibility

- Metal, Plastic, Alloy, Ceramics

- Laser Wavelength

- 1064nm

- Life Span

- Up to 100,000 hours

- Software Interface

- USB, RS232

- Weight

- About 85kg

- Application

- Motorcycle Parts Marking, Serial Marking, Logos, Barcodes

- Voltage

- 220V / 50Hz

- Safety Features

- Protective Housing, Emergency Stop

- Operating Temperature

- 5°C - 40°C

- Automation Grade

- Automatic

- Environment Humidity

- ≤85% RH

- Minimum Character Size

- 0.2mm

- Repeat Frequency

- 20kHz - 100kHz

Motorcycle Parts Marking Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash on Delivery (COD), Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Paypal, Letter of Credit at Sight (Sight L/C), Delivery Point (DP), Cash Against Delivery (CAD), Days after Acceptance (DA), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Motorcycle Parts Marking Machine

Explore the rarefied realm of precision with our Motorcycle Parts Marking Machinean affordable, world-class solution designed for manufacturers and suppliers in India. Enjoy the remarkable deal of unrivaled durability and high-performance automation, supporting a broad spectrum of formats like PLT, BMP, and AI. With a minimum character size of 0.2mm and remarkable accuracy (0.01 mm), it marks on metal, plastic, alloy, or ceramics. Its protective housing and emergency stop ensure heightened safety, while CNC automation enhances productivity. Experience up to 100,000 hours lifespan and seamless integration via USB or RS232, making serial marking, logos, and barcodes effortless.

Versatile Application Areas & Specific Uses

This Motorcycle Parts Marking Machine is ideal for a wide array of application places including workshops, manufacturing plants, and automotive service centers. It handles diverse application media such as metals, plastics, alloys, and ceramics with unparalleled precision. Specifically engineered for motorcycle parts marking, it excels in general use for serial marking, logos, and barcodes. Its exceptional versatility makes it a remarkable tool for both small-scale enterprises and large-scale manufacturers seeking top-tier identification solutions.

Certifications, Export Markets & Secure Shipping

The Motorcycle Parts Marking Machine meets stringent certifications for reliability and safety. Each handover is executed via secure shipping, primarily from FOB ports across India, ensuring prompt and protected delivery. Its significant market value is recognized in major export markets, including Asia, Africa, and Europe. Buyers benefit from the manufacturers commitment to world-class standards and robust after-sales support, making it a preferred choice for global clients seeking rarefied quality and dependable service.

Versatile Application Areas & Specific Uses

This Motorcycle Parts Marking Machine is ideal for a wide array of application places including workshops, manufacturing plants, and automotive service centers. It handles diverse application media such as metals, plastics, alloys, and ceramics with unparalleled precision. Specifically engineered for motorcycle parts marking, it excels in general use for serial marking, logos, and barcodes. Its exceptional versatility makes it a remarkable tool for both small-scale enterprises and large-scale manufacturers seeking top-tier identification solutions.

Certifications, Export Markets & Secure Shipping

The Motorcycle Parts Marking Machine meets stringent certifications for reliability and safety. Each handover is executed via secure shipping, primarily from FOB ports across India, ensuring prompt and protected delivery. Its significant market value is recognized in major export markets, including Asia, Africa, and Europe. Buyers benefit from the manufacturers commitment to world-class standards and robust after-sales support, making it a preferred choice for global clients seeking rarefied quality and dependable service.

FAQs of Motorcycle Parts Marking Machine:

Q: How does the marking process work on different materials?

A: The machine utilizes a 1064nm laser wavelength to mark metals, plastics, alloys, and ceramics with high precision. Its automatic CNC system ensures consistent marking, and users can focus manually or automatically to achieve optimal results.Q: What applications can this marking machine cater to?

A: Primarily designed for motorcycle parts, this machine also supports serial marking, barcodes, logos, and general identification tasks on various components in manufacturing and service environments.Q: Where is this machine best utilized?

A: It is well-suited for workshops, manufacturing plants, and service centers dealing with automotive or engineering parts, especially where precise and durable marking is essential.Q: What benefits do users gain from this machines automation?

A: Automatic grade operation provides increased productivity, minimal human error, consistent quality, and efficient handling of repetitive marking taskssaving time and resources.Q: When should the emergency stop feature be used?

A: The emergency stop button should be used immediately if any unsafe condition arises during operation, ensuring instant cessation of activity to protect the operator and the equipment.Q: What software interfaces are compatible with this machine?

A: The machine supports USB and RS232 interface connections and operates seamlessly with the EZCAD control software for flexible data input and operation control.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Pneumatic Marking Machines Category

Portable VIN Marking Machine

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Condition : New

Usage : Industrial

Product Type : Portable VIN Marking Machine

Dot Pin Marking Machine with rotary

Price 140000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Black

Condition : New

Usage : Industrial

Product Type : Motorcycle Parts Marking Machine

Touch Screen VIN Number Marking Machine

Price 160000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Black

Condition : New

Usage : Industrial

Product Type : Touch Screen VIN Number Marking Machine

Nameplate Steel Metal Pneumatic Marking Machine

Price 140000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Black

Condition : New

Product Type : CNC Nameplate Steel Metal Pneumatic Marking Machine

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry